Understanding Internal & External

Supply Chain Risks

Often used by manufacturers, retailers, and government entities, supply chain risk mitigation involves thorough auditing, vetting, and scoring of suppliers. The goal is to identify risk factors and their potential impact on operations, and create a plan to address them.

Supply Chain Risk Mitigation May Not Be Enough

Managing these supply chain risks is an essential practice, but for manufacturers with complex supply chains, it’s also not enough to fully satisfy stakeholder demands. In today’s market, customers and investors are looking beyond risk management — they want assurances that supply chain operations support wider sustainability goals. This is where the concept of supply chain sustainability management comes in.

Looking beyond just managing risks, supply chain sustainability management is key to creating a strong, adaptable supply chain. It’s all about ensuring your business can continue to expand, innovate responsibly, and achieve goals related to product safety and environmental, social, and governance (ESG). This approach not only ensures that products comply with current regulations but also sets the groundwork for ongoing sustainable business practices and future ESG efforts.

Supply chain sustainability management is essential for complex manufacturers because it shields against disruptions and amplifies brand value. While supply chain risk management is valuable, it is also reactive. On the other hand, a supply chain sustainability solution aids in proactive risk monitoring and mitigation, offering:

- Streamlined Compliance: Gathers extensive data and aligns it with both current and emerging regulations.

- Regulatory Monitoring: Actively notifies businesses of compliance risks through integration with supplier-provided product information.

- Supply Chain Insight: Offers a granular view into supplier performance, ethical sourcing, and compliance.

- Business Intelligence: Generates actionable insights to improve the sustainability of third parties in supply chains.

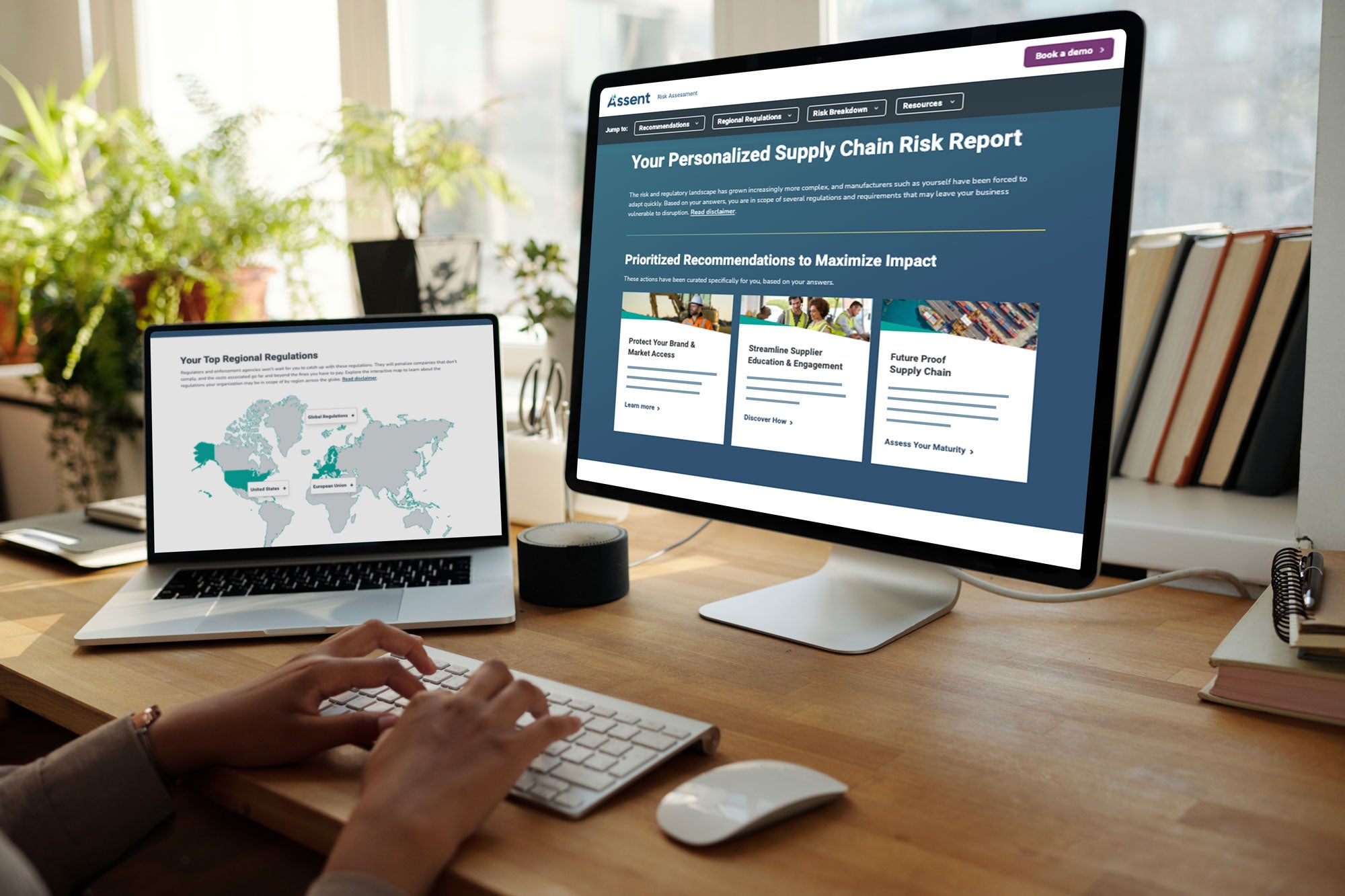

Supply Chain Risk Assessment Tool

Take a moment to evaluate your current risk landscape with the Supply Chain Risk Assessment Tool for Complex Manufacturers. Within minutes, you’ll receive a personalized risk report with actionable insights to safeguard your business.

What Are My Risks?

Looking Beyond Supply Chain Risk Management to Sustainability

Traditional supply chain risk management lays a strong foundation, yet it only marks the start of a more comprehensive journey. Advancing to supply chain sustainability transforms the supply chain into an asset, ensuring resilience against disruptions and compliance failures and protecting your bottom line and brand reputation. This strategic approach is no longer a “nice-to-have” but a best practice for manufacturers looking to maintain market access and gain a competitive advantage.

This is why forward-thinking organizations are turning to solutions like Assent. We help companies take a proactive approach to supply chain sustainability that keeps them ahead of regulatory changes, enhances their supplier engagement, and meets increasing investor, customer, and stakeholder ESG demands.